Customer consultation product demand and price.

In order to meet all customer's superior experiences in time, we provide customers with a variety of service options: headquarters dedicated line 7x24-hour response service, product features video operation and real-time video solutions. To improve the quality and efficiency of the nice public service, we have set up cooperation service outlets and service centers directly under the cities and counties in the country, and also set up an application team of experts to provide solutions to the problems in complex applications the solution. Not only that, we also offer tailor-made pump control solutions and extended services to meet different customers' needs.

-

01

Consultative

-

02

Design

Design drawings according to customer requirements, and confirm to customers.

-

03

Sample

Make samples and send them to customers for confirmation.

-

04

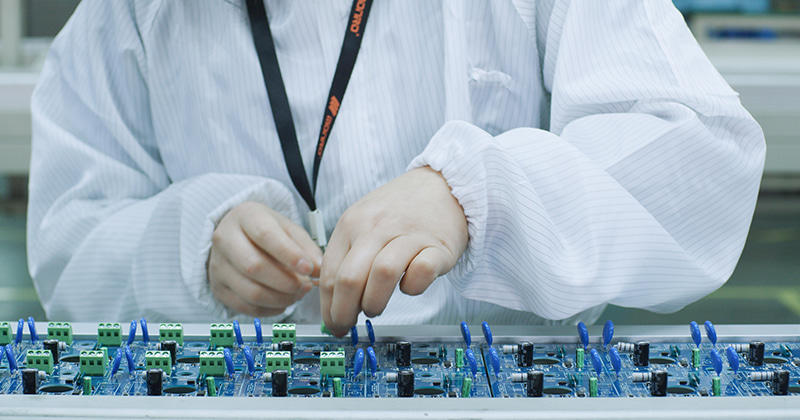

Production

After confirming the sample and sending the order, mass production will start.

CASTING QUALITY CONTACT US

-

0

MOQ

-

0K

Daily output

-

0Years

Warranty period

-

0h

Customer service

简体中文

简体中文 English

English Español

Español