Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Investigating the Power Consumption Devices of Pressure Switch Factory

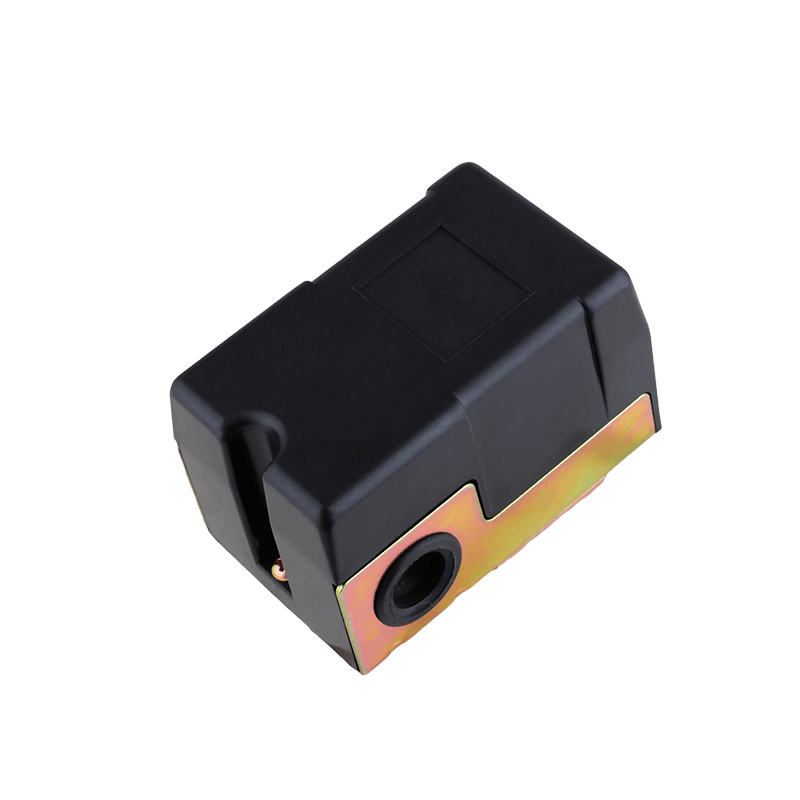

Custom Pressure Control Switch Factory Manufacturer in China

In the realm of industrial automation, the power consumption of components such as pressure switches is a critical factor that impacts both operational efficiency and cost-effectiveness. Pressure Switch Factory, known for its commitment to innovation and sustainability, has been at the forefront of developing low-power consumption pressure switches that meet the demands of modern industries. This article will delve into the power consumption characteristics of the pressure switches produced by Pressure Switch Factory, examining how they contribute to energy efficiency and sustainable practices.

The Pressure Switch Factory has always been conscious of the environmental footprint left by its products, and as such, it has invested heavily in research and development to create pressure switches that not only perform their function with precision but also do so with energy usage. Their pressure switches are designed with energy efficiency in mind, utilizing advanced microcontrollers and optimized algorithms that reduce power consumption without compromising on performance.

One of the key aspects of the Pressure Switch Factory's approach to power consumption is the use of sleep modes and wake-on-demand functionality. By allowing the pressure switch to enter a low-power state when not actively measuring pressure, the factory's devices can significantly reduce their overall energy use. When a change in pressure is detected that requires action, the switch wakes up, performs the necessary measurements, and then returns to its low-power state, all without manual intervention.

In addition to sleep modes, the Pressure Switch Factory also employs energy-saving materials and components in the construction of their pressure switches. The use of high-quality, energy-efficient sensors and electronic components ensures that the switches consume less power while maintaining high levels of accuracy and responsiveness. This attention to detail in materials and design has allowed the Pressure Switch Factory to produce pressure switches that are not only reliable but also environmentally friendly.

The Pressure Switch Factory also recognizes the importance of software in managing power consumption. Their switches are equipped with intelligent software that can adjust the sampling rate and measurement frequency based on the application's requirements. This adaptive approach to power management ensures that the pressure switch only uses the energy necessary for the task at hand, further reducing overall power consumption.

The factory's commitment to energy efficiency is also evident in its continuous efforts to improve the energy performance of its pressure switches. By staying abreast of advancements in technology and materials, the Pressure Switch Factory is able to incorporate new innovations into its products, ensuring that its pressure switches remain at the forefront of low-power, high-performance industrial components.

In conclusion, the Pressure Switch Factory's dedication to reducing power consumption in their pressure switches is a testament to their focus on sustainability and efficiency. By employing a combination of advanced technology, energy-saving materials, and intelligent software, the factory has been able to produce pressure switches that consume less power while maintaining high levels of performance. This commitment to energy efficiency not only benefits the industries that rely on their products but also contributes to a more sustainable future for all.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español