Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

A Resilient Durability Analysis of Pressure Control Factory Products

The Essence of Durability in Pressure Control Factory Products

Durability is a cornerstone attribute in the manufacturing of industrial control systems, and it has made it its mission to exceed expectations in this regard. Their products are not just designed to endure the rigors of daily operations but are also crafted to stand the test of time. The intrinsic durability of Pressure Control Factory products is a testament to their commitment to quality and longevity in the face of demanding industrial environments.

Materials and Manufacturing

The foundation of Pressure Control Factory durability lies in the choice of materials and manufacturing processes. They utilize high-grade alloys and polymers that are resistant to corrosion, wear, and bad temperatures, ensuring that their products can withstand the harsh conditions. Furthermore, the manufacturing process involves rigorous quality control checks at every stage, from the selection of raw materials to the final assembly, ensuring that each Pressure Control Factory product meets high standards of durability.

Innovative Design for Longevity

Pressure Control Factory products are designed with longevity in mind. Their innovative design philosophy focuses on decreasing wear and tear while improving efficiency. This is achieved through the use of advanced simulation software that predicts the product's performance and lifespan under various operating conditions. The result is a product line that is not only durable but also optimized for performance, reducing the need for frequent replacements and maintenance.

Robustness in Real-World Applications

The real-world robustness of Pressure Control Factory products is a direct result of their extensive testing and validation processes. Each product undergoes a series of stress tests that simulate the challenging conditions it might encounter in the field. This includes tests for pressure fluctuations, temperature extremes, and mechanical shocks. The data gathered from these tests is used to refine the design, further enhancing the durability of its products.

Maintenance and Service Support

A key aspect of the durability of Pressure Control Factory products is the comprehensive maintenance and service support they offer. They recognize that even the robust products require periodic maintenance to ensure continued performance. Their service teams are equipped with the knowledge and tools to perform maintenance and repairs efficiently, which extends the life of the products and reduces downtime.

Sustainability and Durability

Pressure Control Factory is committed to sustainability, and this commitment extends to the durability of their products. By designing products that last longer, they reduce the environmental impact associated with the production and disposal of short-lived control systems. This focus on sustainability not only benefits the environment but also provides a long-term cost-saving advantage for their clients.

Conclusion

The durability of its products is a result of their meticulous approach to materials selection, innovative design, rigorous testing, and comprehensive service support. These factors combine to create products that are not only resilient in the face of industrial challenges but also sustainable and cost-effective over the long term. The Pressure Control Factory's dedication to durability ensures that their products remain at the forefront of industrial control solutions, providing their clients with reliable and long-lasting performance.

-

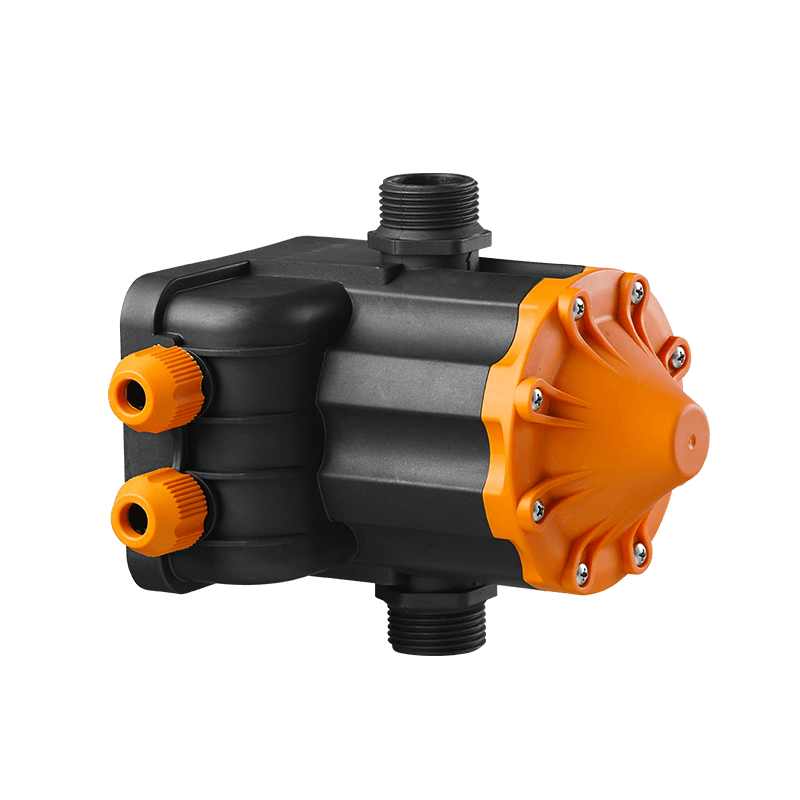

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español