Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Assessing Vibration and Shock Resistance Features in Pressure Switch Factory Systems

Industrial environments often expose pressure control systems to significant vibration and mechanical shocks, which can affect the performance, accuracy, and longevity of pressure switches. Maintaining reliable operation under such conditions is critical to ensure system safety and prevent process disruptions. Evaluating whether a Pressure Switch Factory system incorporates vibration-resistant and shock-absorbing design elements helps engineers and facility managers select the right solution for demanding industrial applications.

Importance of Vibration-Resistant Design

Vibration can cause mechanical fatigue, loosening of internal components, and erratic contact activation in pressure switches. Effective vibration-resistant design includes reinforced housing structures, stabilized internal mechanisms, and secure mounting systems. By reducing the transmission of mechanical vibrations to sensitive components, these features help maintain accurate actuation and prevent premature wear. In high-vibration environments, such as pumps, compressors, or heavy machinery operations, this design consideration is essential for reliable pressure monitoring.

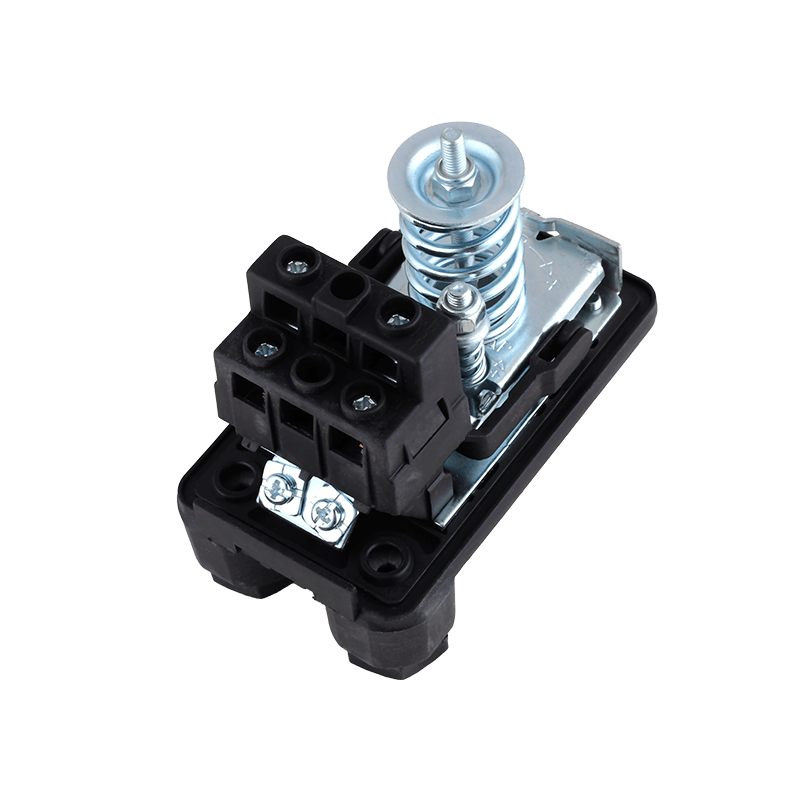

Shock Absorption and Mechanical Resilience

Mechanical shocks, such as sudden impacts or transient forces, pose a different challenge. Pressure switches must withstand these forces without deformation or internal damage. Shock-resistant systems often incorporate damping elements, reinforced diaphragms, and protective housings that absorb impact energy. These features ensure that critical components, including contacts, springs, and sensors, remain intact and functional. Properly engineered shock resistance reduces the risk of false triggering or permanent damage during unexpected mechanical events.

Material Selection and Structural Integrity

Materials play a vital role in enhancing vibration and shock resistance. High-strength metals such as stainless steel or hardened alloys provide structural stability and prevent deformation. Internal components, including springs and diaphragms, are often crafted from fatigue-resistant alloys to withstand repeated vibration and impact cycles. By combining robust materials with thoughtful structural design, pressure switch systems maintain both accuracy and durability under challenging mechanical conditions.

Electrical and Contact Protection

Vibration and shocks can also affect the electrical contacts within a pressure switch. Loose or misaligned contacts may cause intermittent signals, delayed actuation, or complete failure. Pressure Switch Factory systems often employ design strategies such as contact stabilization, spring preloading, and reinforced terminals to prevent electrical malfunction. These measures ensure that the switch provides consistent, reliable signals even when exposed to mechanical stress.

Testing and Certification for Harsh Conditions

Reliable systems undergo rigorous testing to validate their performance under vibration and shock. Simulated mechanical stress tests, including vibration tables and impact testing, assess the system’s durability and response accuracy. Certified systems meet industrial standards, such as IEC or ISO guidelines, assuring that they can endure the operational stresses of real-world industrial environments. Testing helps identify design weaknesses and confirms that the system can operate safely and accurately over long-term use.

Operational Benefits of Vibration and Shock Resistance

Pressure switches with vibration and shock-resistant designs offer several operational advantages. They maintain accuracy and repeatability, reduce maintenance requirements, and reduce the risk of system downtime due to mechanical failure. Industries such as oil and gas, chemical processing, and manufacturing benefit from switches that remain stable and reliable even in high-vibration or impact-prone applications. Enhanced resilience also prolongs component lifespan, resulting in lower overall operational costs.

The incorporation of vibration and shock-resistant features in a Pressure Switch Factory system is critical for maintaining accurate, reliable, and durable performance in demanding industrial settings. Through careful material selection, reinforced structural design, protective electrical components, and rigorous testing, these systems can withstand harsh mechanical conditions. Investing in vibration- and shock-resistant pressure switches ensures safe, efficient, and long-lasting operation, providing significant advantages for high-stress industrial applications.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español